Vibration analysis and its Diagnostics Services

Civi Land Co. is proud of have the most reputed vibration analysis experts in the team. We have certified ISO/IEC 18436-2 CAT- II & III Vibration Analyst – one of the very few in the county – heading the Vibration Analysis services for Civi Land Co. and evaluating the machinery health condition of our valuable customers

Vibration analysis is defined as a process for measuring the vibration levels and frequencies of machinery and then using that information to analyze how healthy the machines and their components.

We also ensure that our engineers use world class equipment and high-end Vibration Analyzers for their vibration analysis & its diagnostic purposes & field balancing.

Anytime a piece of machinery is running, it is making vibrations. An accelerometer attached to the machine generates a voltage signal that corresponds to the amount of vibration and the frequency of vibration the machine is producing All data collected from the accelerometer goes directly into a data collector (software), which records the signal as either amplitude vs. time (known as time waveform), amplitude vs. frequency (known as fast Fourier transform), or both. All of this data is analyzed by computer program algorithms, which in turn is analyzed by engineers or trained vibration analysts to determine the health of the machine and identify possible impending problems like Unbalance

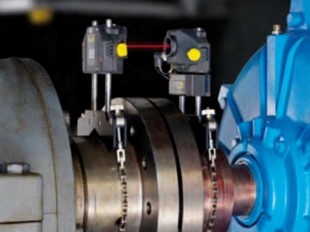

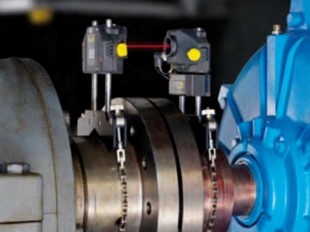

Laser Shaft Alignment Services

Shaft alignment, often called “coupling alignment”, is a process to make two or more rotating shafts co-linear, or in the same straight line, both vertically and horizontally. Shaft alignment can be done utilizing several methods and tools, such as straightedges, calipers, dial indicators, optics, or laser systems. Of these, laser shaft alignment is the fastest and most accurate. Power transmission through drive and driven shafts – shaft alignment / drive and driven pulleys – pulley alignment, need to be within

tolerance to operate the equipment with acceptable level of vibration thereby increasing

the life of machine components and save energy.

Infrared Thermography Services

Infrared thermography is NDT or predictive maintenance technique, which detects infrared energy emitted from object by its wavelength, converts it to temperature, and displays image of temperature distribution. Infrared thermography used to monitor real time temperature images without contacting an object of plant machinery, electrical systems, aircraft and building structure.

Our infrared thermographers are using world class Infrared thermal cameras and doing thermal survey very precisely. After colour images stored for further analysis, IR report will be prepared and reviewed by ASNT Level-II certified Infrared Thermographer.

Safety

Opening panels and doors for infrared inspection of live electrical installations greatly increases the risk of arc-flash injury Ensure Proper PPE as per Arc flash Rating.

Typical Electrical Applications

Typical Mechanical Applications

-

Motors

-

Pumps

-

Heat exchangers

-

Bearings

-

Gearboxes

-

Drive belts

Typical Process Applications

-

Refractory insulation

-

Tanks and vessels

-

Steam systems/traps

-

Pipes and valves

-

Heaters/Furnaces

-

Manufacturing equipment

-

Plastics Industry (Molding)

-

Pulp & Paper (Rollers, handling equipment, etc)

-

Metal Foundry

-

Boilers and Reactors

-

Research & Development